Battery Manufacturing Automation

Battery Manufacturing Automation

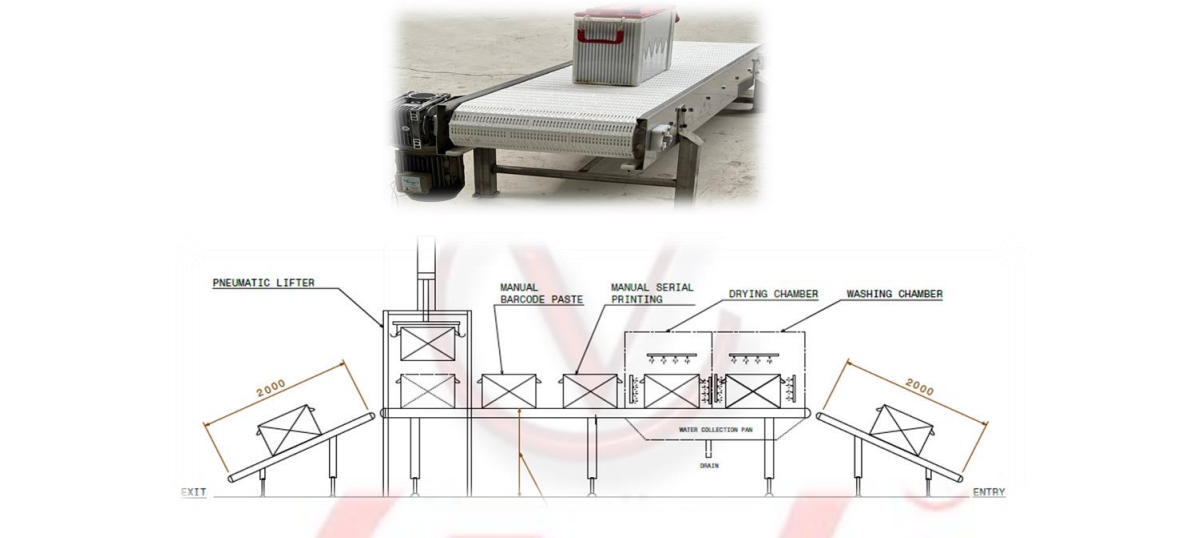

The automation solution for battery manufacturing, designed and manufactured by VMPL, encompasses several key processes, including washing, drying, serial printing, barcode paste, and battery packing. The automated washing machine ensures thorough cleaning of batteries with precision temperature control and spray nozzles. The drying tunnel then efficiently dries the batteries with controlled temperature and air flow. Next, a high-resolution inkjet printer prints unique serial numbers, logos, and other relevant information on battery labels. An automated label applicator then applies barcode labels to the battery packs. Finally, an automated packaging system places the batteries in cases or trays, with options for custom packaging configurations.

This comprehensive automation solution increases efficiency and productivity while improving accuracy and consistency. By reducing labor costs and improving worker safety, it addresses key concerns in the battery manufacturing process. The solution is customizable to meet specific production requirements and can be integrated with existing equipment and systems. By enhancing product quality and reliability, improving traceability and inventory management, and increasing customer satisfaction, this automation solution provides numerous benefits. Additionally, it reduces production time and costs while offering a scalable design to accommodate growing demands.